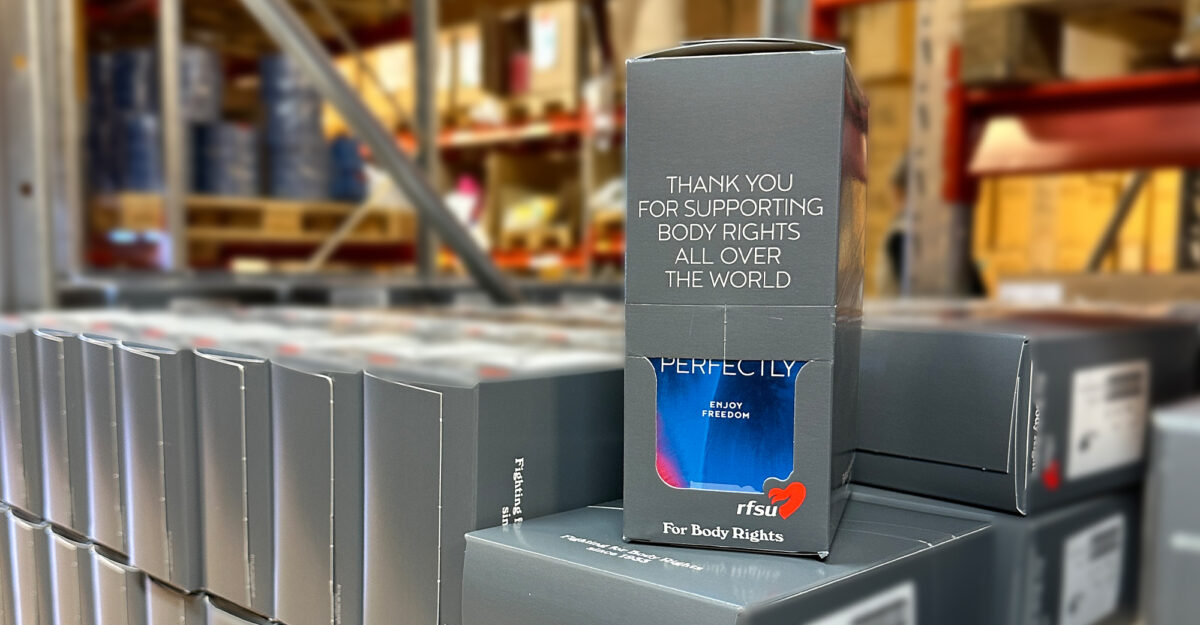

RFSU focuses on sustainable packaging

Products from RFSU are designed to give people a greater sense of well-being, a higher quality of life and a safer sex life. But that isn't all - RFSU's focus is also on minimizing the climate footprint by using sustainable packaging.

RFSU wants to offer safe products for everyone – regardless of gender, sexual orientation, functional ability, size or preference. It is also important that the products should be available at many points of sale – so they are easy to acquire when you need them.

The products are developed by RFSU AB based on a wide range of people’s needs, and behind every product launch there is a lot of solid work – including taking into account the climate footprint of the products.

Nicklas Gustafsson. who works with sustainability issues and strategic purchasing at RFSU AB, explains that over the past year they have shifted into higher gear to reduce the business’s climate impact.

“We don’t want to get stuck in old patterns, so we have invested in challenging ourselves to find new ways to lower our climate footprint.” he says.

Among other things, large parts of the supplier and production chain have been reviewed, to identify both large and small measures to make the products more sustainable.

“We have mapped our total material consumption and developed a number of initiatives to make our products and packaging more sustainable”, says Nicklas Gustafsson.

To determine the total climate footprint of a product or packaging, you need to keep track of not just the material of the packaging but also calculate every step in the supply chain.

“Which is why we have measured and weighed all materials as well as calculated the emissions of each transport.”

An example of a fairly simple measure RFSU AB has taken that had a significant impact was changing from a foreign paper supplier to a Swedish one.

“By changing suppliers, we cut the transport distance considerably and succeeded in reducing our climate footprint from paper packaging by a whopping 55 percent in 2023”, says Nicklas Gustafsson.

RFSU AB says no thanks to unnecessary plastic

Another measure RFSU AB has taken is to remove all unnecessary plastic from packaging – and to use recycled plastic as much as possible in cases where plastic packaging is necessary, for example for products that contain liquids.

“Plastic containers or packaging has unique properties to hold in moisture. There is also paper packaging with thin layers of plastic that has the same moisture-retaining properties, but we prefer so-called monomaterials, where the packaging is made of a single material. Because this kind of packaging is easier to recycle”, says Nicklas Gustafsson.

The products in RFSU AB’s assortment are sold in digital sales channels as well as in physical stores within the grocery trade, pharmacies, beauty and health stores, kiosks and gas stations in Sweden, Norway, Finland and Denmark. Many retailers have been involved in RFSU AB’s sustainability journey and have been positive about the changes.

“At physical brick & mortar stores, we have started a journey to eliminate the plastic trays that the products are in, replacing them with paper trays”, says Nicklas Gustafsson.

RFSU AB invests in circular materials

Another way to reduce the packaging’s climate footprint has been to invest in recyclable materials in RFSU’s products.

“For example, we used recycled plastic for the packaging in the menopause series FemCare, which was launched in 2023”, says Nicklas Gustafsson.

The packaging in RFSU’s FemCare intimate care range is made from recycled plastic, the food supplements made from recycled PET and the packaging for the lubricant made partly from recycled PE*.

“By using recycled materials for packaging, we reduced our carbon dioxide emissions by roughly 20 percent, compared to if we had chosen virgin material.”

*Polyethylene (PE) is a plastic material well-suited for tubes and bottles, for example, and is often usen in commercial operations. Recycled PE is produced by collecting used plastic items made from polyethylene, cleaning them and melting them down. The material can then be reused to create new plastic products and packaging.

Deposit return on recycled products from RFSU

In early 2024, RFSU started a collaboration with Bower, a recycling app that allows the consumer to scan their packaging when it’s time to discard the packaging in order to get a deposit return. Just like when returning PET bottles and aluminum cans for deposit, the consumer receives a bonus for each packaging recycled.

Bower’s ambition is to inspire a circular lifestyle and to get as many people as possible to sort their packaging into the correct container at the recycling station or in their waste sorting at home – so that no material ends up in the garbage.

During the first ten months the collaboration has been underway, 40,000 packages from the brands RFSU, Carmex and Tunto have been scanned and recycled using the Bower app on the Nordic market.

“One great thing about the Bower app is we can send targeted information to selected consumer groups, for example how to throw away condoms or how a package should be sorted at recycling stations. We also think using the app will make recycling a bit more fun”, says Nicklas Gustafsson.

RFSU designs sustainably from the start

The new requirements for recycled plastic raw material within the framework of the PPWR (Packaging and Packaging Waste Regulation) proposed by the European Commission aim to reduce packaging waste and increase the use of recycled material. The regulation, which is part of the EU’s green deal and circular economy, sets specific targets for recycled plastics in packaging to reduce the environmental impact of plastics and promote a circular economy.

The regulation includes, stricter requirements to reduce product’s weight and volume, in order to cut down on the amount of transports and reduce emissions.

Which is why it is increasingly important to consider sustainability issues early in product development, something RFSU AB has taken to heart.

Our climate footprint decreased by 6.5 percent in 2023 compared to the previous year, even though our turnover increased by 13 percent. Nicklas Gustafsson, responsible for sustainability issues and strategic purchasing at RFSU AB.

“By choosing packaging that contains only as much air as needed for the particular product, a larger number of products can be transported on the same load carrier”, says Nicklas Gustafsson. “And to ensure the packaging can be easily recycled, we are careful with our choice of materials, labels, color and glue.”

RFSU AB’s work to leave no stone unturned to reduce the products’ climate footprint has yielded positive results.

“Our climate footprint decreased by 6.5 percent in 2023, compared to the previous year, despite our turnover increasing by 13 percent”, says Nicklas Gustafsson. “We are proud of our sustainability journey and our work to reduce our climate footprint from our packaging.”

Read about in RFSU AB’s entire sustainability work in 2023.